2023 China Desain Anyar Stainless Steel Paper Drinking Straw Pipe Making Machine

Kunci sukses kita yaiku "Produk utawa layanan sing apik Kualitas dhuwur, Tarif sing Wajar lan Layanan sing Efisien" kanggo 2023 China New Design Stainless Steel Paper Drinking Straw Pipe Making Machine, Kualitas paling apik, rega sing kompetitif, pangiriman cepet lan layanan sing bisa dipercaya dijamin.

Kunci sukses kita yaiku "Produk utawa layanan sing apik Kualitas dhuwur, Tarif sing Wajar lan Layanan sing Efisien" kanggoChina Paper Straw Making Machine lan Paper Straw Extrusion Machine, Perusahaan kita wis lulus standar ISO lan kita ngormati paten lan hak cipta pelanggan. Yen customer menehi designs dhewe, Kita bakal njamin sing padha bakal mung siji bisa duwe solusi sing. Muga-muga kanthi barang sing apik bisa nggawa rejeki sing apik kanggo para pelanggan.

Katrangan

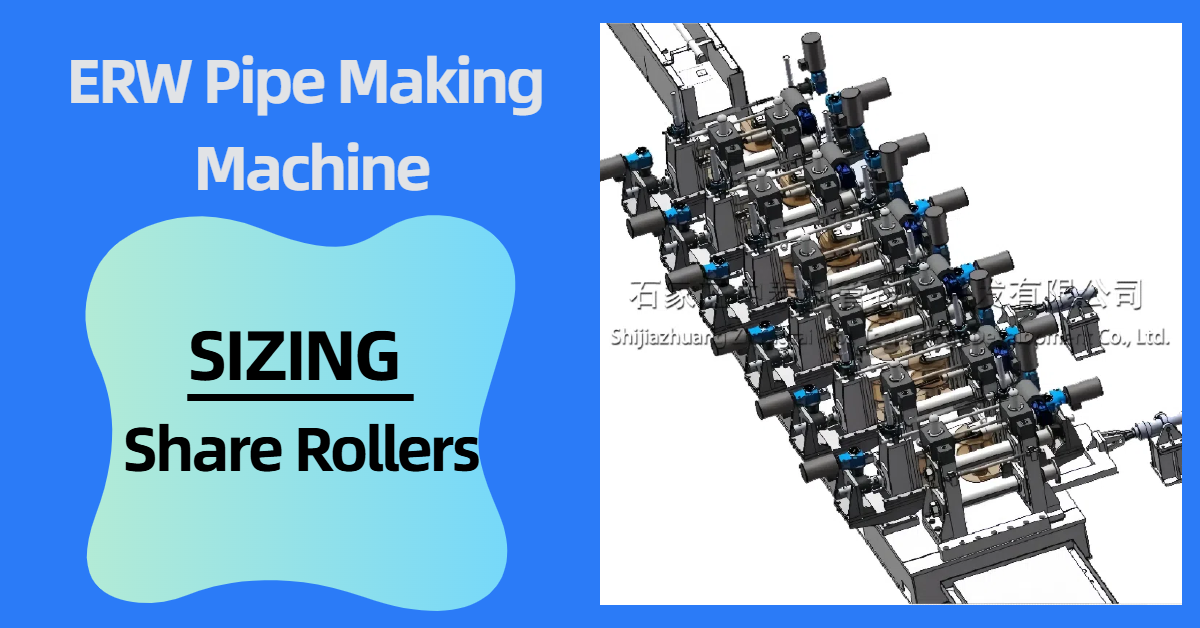

ERW (Electric Resistance Weld) Tube Mill iku kanggo bisa liwat coil uncoiled lan feed menyang mbentuk bagean liwat peralatan saka bagean entri. Entri bagean mbisakake pabrik tabung kanggo mbukak terus-terusan kanthi nggunakake Strip gabung lan accumulator. Sadurunge welding pipe, pipe kawangun ing wangun bunder liwat seri mimpin lan idler rollers saka mbentuk bagean. Ing bagean welding, pipa dilas kanthi longitudinal kanthi nggunakake metode las induksi frekuensi dhuwur. Manik njaba dicopot lan dibentuk kanthi bentuk kethokan. Jahitan las disetrika lan pipa ngliwati bagean pendinginan. Banjur ing bagean ukuran, pipa dibentuk kanggo ukuran sing ditemtokake lan diowahi dadi bentuk sing ditemtokake. Sawise ukuran, pipa dipotong nganti dawa sing dibutuhake kanthi nggunakake peralatan sing dipotong lan dikirim menyang meja ngumpulake sawise ngliwati conveyor.

Pabrik pipa gandheng HF lengkap digawe saka bagean entri, bagean pabrik, bagean potong lan bagean finishing, proses manufaktur pipa baja kalebu:

Scrolling Up→ Uncoiling → Shear and Welding → Spiral Accumulator → Forming → HF induction Welding → External Burr Removing → Cooling → Sizing → Flying Saw → Run Out Table → Inspecting → Packing→ Warehouse

Fitur:

1. Cocog kanggo ngolah baja karbon

2. Pipa bunder lan persegi dowo bisa diprodhuksi nganggo peralatan iki

3. Kacepetan produksi bisa nganti 120m / min

4.Diameter toleransi kesalahan ing 0,5/100 saka OD pipe kang

informasi produk

| Produk & hasil | Pipa Bundar | 10mm-89mm |

| Tabung persegi & persegi panjang | 10x10mm-70x70mm | |

| dawa | 6-12m | |

| Kacepetan Produksi | 50-120m / min | |

| Kapasitas produksi | 15000 Ton | |

| Konsumsi | Kapasitas dipasang pabrik | 300KW-750KW |

| Area Line | 40X5M-80X10m | |

| buruh | 6-8 buruh | |

| Bahan Baku | Bahan | ST-37 ST-52 X42 X48 X52 X60 X70 |

| Jembar | 120mm-280mm | |

| ID koil | Φ470-508 mm | |

| Koil OD | Φ1000 ~ 1800 mm | |

| Bobot Coil | 2-5Ton |

Kaluwihan Kita

1) Luwih saka 20 taun riset lan pangembangan independen lan pengalaman manufaktur. Lulus sertifikasi sistem mutu ISO9001 lan melu nyiapake sawetara standar industri.

2) Kustomisasi dhukungan ZTZG miturut standar internasional ing saben wilayah, lan nyedhiyakake informasi teknis lan dhukungan pelatihan teknis biasa.

3) Ana kontrol kualitas sing ketat ing bahan mentah, akurasi pangolahan, perawatan panas, akurasi perakitan, bagean standar, lan liya-liyane. Tingkat pass pangiriman peralatan yaiku 100%.

Tombol kanggo sukses kita yaiku "Produk utawa layanan sing apik Kualitas dhuwur, Tarif sing Cukup lan Layanan sing Efisien" kanggo 2019 China New Design Stainless Steel Paper Drinking Straw Pipe Making Machine, Kualitas paling apik, rega sing kompetitif, pangiriman cepet lan layanan sing bisa dipercaya.

| ERW TUBE MILL LINE | |||||

| Model | Rpipa udud mm | Alun-alunpipa mm | kekandelan mm | Nyambut gawe m/min | |

| ERW20 | Ф8-Ф20 | 6x6-15×15 | 0.3-1.5 | 120 | Waca liyane |

| ERW32 | Ф10-Ф32 | 10×10-25×25 | 0.5-2.0 | 120 | |

| ERW50 | Ф20-Ф50 | 15×15-40×40 | 0.8-3.0 | 120 | |

| ERW76 | Ф32-Ф76 | 25×25-60×60 | 1.2-4.0 | 120 | |

| ERW89 | Ф42-Ф89 | 35×35-70×70 | 1.5-4.5 | 110 | |

| ERW114 | Ф48-Ф114 | 40×40-90×90 | 1.5-4.5 | 65 | |

| ERW140 | Ф60-Ф140 | 50×50-110×110 | 2.0-5.0 | 60 | |

| ERW165 | Ф76-Ф165 | 60×60-130×130 | 2.0-6.0 | 50 | |

| ERW219 | Ф89-Ф219 | 70×70-170×170 | 2.0-8.0 | 50 | |

| ERW273 | Ф114-Ф273 | 90×90-210×210 | 3.0-10.0 | 45 | |

| ERW325 | Ф140-Ф325 | 110×110-250×250 | 4.0-12.7 | 40 | |

| ERW377 | Ф165-Ф377 | 130×130-280×280 | 4.0-14.0 | 35 | |

| ERW406 | Ф219-Ф406 | 170×170-330×330 | 6.0-16.0 | 30 | |

| ERW508 | Ф273-Ф508 | 210×210-400×400 | 6.0-18.0 | 25 | Waca liyane |

| ERW660 | Ф325-Ф660 | 250×250-500×500 | 6.0-20.0 | 20 | Waca liyane |

| ERW720 | Ф355-Ф720 | 300×300-600×600 | 6.0-22.0 | 20 | Waca liyane |

| LINE PRODUKSI PIPA STAINLESS STEEL | |||||

| Model | Rpipa udud mm | Alun-alunpipa mm | kekandelan mm | kacepetan kerja m/min | |

| SS25 | Ф6-Ф25 | 5×5-20×20 | 0.2-0.8 | 10 | Waca liyane |

| SS32 | Ф6-Ф32 | 5×5-25×25 | 0.2-1.0 | 10 | Waca liyane |

| SS51 | Ф9-Ф51 | 7×7-40×40 | 0.2-1.5 | 10 | Waca liyane |

| SS64 | Ф12-Ф64 | 10×10-50×50 | 0.3-2.0 | 10 | Waca liyane |

| SS76 | Ф25-Ф76 | 20×20-60×60 | 0.3-2.0 | 10 | Waca liyane |

| SS114 | Ф38-Ф114 | 30×30-90×90 | 0.4-2.5 | 10 | Waca liyane |

| SS168 | Ф76-Ф168 | 60×60-130×130 | 1.0-3.5 | 10 | Waca liyane |

| SS219 | Ф114-Ф219 | 90×90-170×170 | 1.0-4.0 | 10 | Waca liyane |

| SS325 | Ф219-Ф325 | 170×170-250×250 | 2.0-8.0 | 3 | Waca liyane |

| SS426 | Ф219-Ф426 | 170×170-330×330 | 3.0-10.0 | 3 | Waca liyane |

| SS508 | Ф273-Ф508 | 210×210-400×400 | 4.0-12.0 | 3 | Waca liyane |

| SS862 | Ф508-Ф862 | 400×400-600×600 | 6.0-16.0 | 2 | Waca liyane |