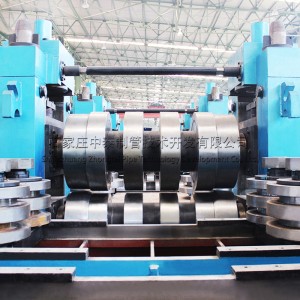

Tube MillERW114 HF Straight Welded Pipe Line Produksi

Katrangan

Line produksi pipa gandheng frekuensi dhuwur utamane digunakake kanggo produksi terus-terusan pipa gandheng jahitan lurus. Iki nganggo welding induksi frekuensi dhuwur, sing ora mung bisa ngasilake pipa bunder nanging uga pipa persegi sing cocog lan pipa berbentuk khusus. Mesin welding pipa frekuensi dhuwur utamane digunakake kanggo produksi macem-macem pipa wesi, pipa konstruksi, pipa struktural, pipa banyu, pipa minyak, Pipa API, lan liya-liyane.

Taliran eknis

Gulung munggah → Uncoiling → Shear and Welding → Spiral accumulator → Forming → HF induction welding → External burr removing → Cooling → Sizing → Flying saw → Run out table → Inspecting → Packing → Warehouse

Fproses orming

| Pipa bunder | Proses pembentukan gulungan kadhemen | Desain roller apik |

| Skere & pipa persegi panjang | Proses umum babak-kanggo-kotak | Proses mbentuk stabil |

| Bunder-kanggo-alun karo sirah Turki | Kualitas pipa apik |

Informasi Teknis Dasar Jalur Produksi Pipa Las

| Produk & hasil | Pipa Bundar | 48mm-114Ketebalan mm:1.5 mm-4.5 mm |

| Tabung persegi & persegi panjang | 40mm ×40 mm -90mm ×90Ketebalan mm:1.5 mm-4.0mm | |

| dawa | 6m-12m Dawane Toleransi: ± 3mm | |

| Kacepetan Produksi | 20-65m/min | |

| Kapasitas produksi | 30,000 ton / taun | |

| Konsumsi | Kapasitas dipasang pabrik | 160 kw |

| Area Line | 78m (dawa) ×6m (jembaré) | |

| buruh | 6-8 buruh | |

| Bahan Baku | Bahan | Q235B(ASTM GR·D,σs 230) |

| Jembar | 150mm-36Ketebalan 0 mm:1.5 mm-4.5 mm | |

| ID koil | 550-610 mm | |

| Koil OD | Maks 1600 mm | |

| Bobot Coil | 4,0t |

Kaluwihan

Kaluwihan peralatan:

√Nalika ngasilake pipa bunder, bisa nggunakake teknik mbentuk ZTF.

√Nalika ngasilake tabung persegi & persegi dowo, bisa nggunakake teknik langsung kothak-kotak (DSS).

Produk: tabung struktur arsitektur, tabung cairan tekanan rendah, tabung sabuk transmisi batu bara, tabung poros penggerak, tabung pagar, tabung pijakan menara, tabung baja balok mobil lan produk liyane.

Detail Produk

| ERW TUBE MILL LINE | |||||

| Model | Rpipa udud mm | Alun-alunpipa mm | kekandelan mm | Nyambut gawe m/min | |

| ERW20 | Ф8-Ф20 | 6x6-15×15 | 0.3-1.5 | 120 | Waca liyane |

| ERW32 | Ф10-Ф32 | 10×10-25×25 | 0.5-2.0 | 120 | |

| ERW50 | Ф20-Ф50 | 15×15-40×40 | 0.8-3.0 | 120 | |

| ERW76 | Ф32-Ф76 | 25×25-60×60 | 1.2-4.0 | 120 | |

| ERW89 | Ф42-Ф89 | 35×35-70×70 | 1.5-4.5 | 110 | |

| ERW114 | Ф48-Ф114 | 40×40-90×90 | 1.5-4.5 | 65 | |

| ERW140 | Ф60-Ф140 | 50×50-110×110 | 2.0-5.0 | 60 | |

| ERW165 | Ф76-Ф165 | 60×60-130×130 | 2.0-6.0 | 50 | |

| ERW219 | Ф89-Ф219 | 70×70-170×170 | 2.0-8.0 | 50 | |

| ERW273 | Ф114-Ф273 | 90×90-210×210 | 3.0-10.0 | 45 | |

| ERW325 | Ф140-Ф325 | 110×110-250×250 | 4.0-12.7 | 40 | |

| ERW377 | Ф165-Ф377 | 130×130-280×280 | 4.0-14.0 | 35 | |

| ERW406 | Ф219-Ф406 | 170×170-330×330 | 6.0-16.0 | 30 | |

| ERW508 | Ф273-Ф508 | 210×210-400×400 | 6.0-18.0 | 25 | Waca liyane |

| ERW660 | Ф325-Ф660 | 250×250-500×500 | 6.0-20.0 | 20 | Waca liyane |

| ERW720 | Ф355-Ф720 | 300×300-600×600 | 6.0-22.0 | 20 | Waca liyane |

| LINE PRODUKSI PIPA STAINLESS STEEL | |||||

| Model | Rpipa udud mm | Alun-alunpipa mm | kekandelan mm | kacepetan kerja m/min | |

| SS25 | Ф6-Ф25 | 5×5-20×20 | 0.2-0.8 | 10 | Waca liyane |

| SS32 | Ф6-Ф32 | 5×5-25×25 | 0.2-1.0 | 10 | Waca liyane |

| SS51 | Ф9-Ф51 | 7×7-40×40 | 0.2-1.5 | 10 | Waca liyane |

| SS64 | Ф12-Ф64 | 10×10-50×50 | 0.3-2.0 | 10 | Waca liyane |

| SS76 | Ф25-Ф76 | 20×20-60×60 | 0.3-2.0 | 10 | Waca liyane |

| SS114 | Ф38-Ф114 | 30×30-90×90 | 0.4-2.5 | 10 | Waca liyane |

| SS168 | Ф76-Ф168 | 60×60-130×130 | 1.0-3.5 | 10 | Waca liyane |

| SS219 | Ф114-Ф219 | 90×90-170×170 | 1.0-4.0 | 10 | Waca liyane |

| SS325 | Ф219-Ф325 | 170×170-250×250 | 2.0-8.0 | 3 | Waca liyane |

| SS426 | Ф219-Ф426 | 170×170-330×330 | 3.0-10.0 | 3 | Waca liyane |

| SS508 | Ф273-Ф508 | 210×210-400×400 | 4.0-12.0 | 3 | Waca liyane |

| SS862 | Ф508-Ф862 | 400×400-600×600 | 6.0-16.0 | 2 | Waca liyane |