φ219×10 Jalur Produksi Pipa Angkutan Minyak & Gas (API).

Katrangan

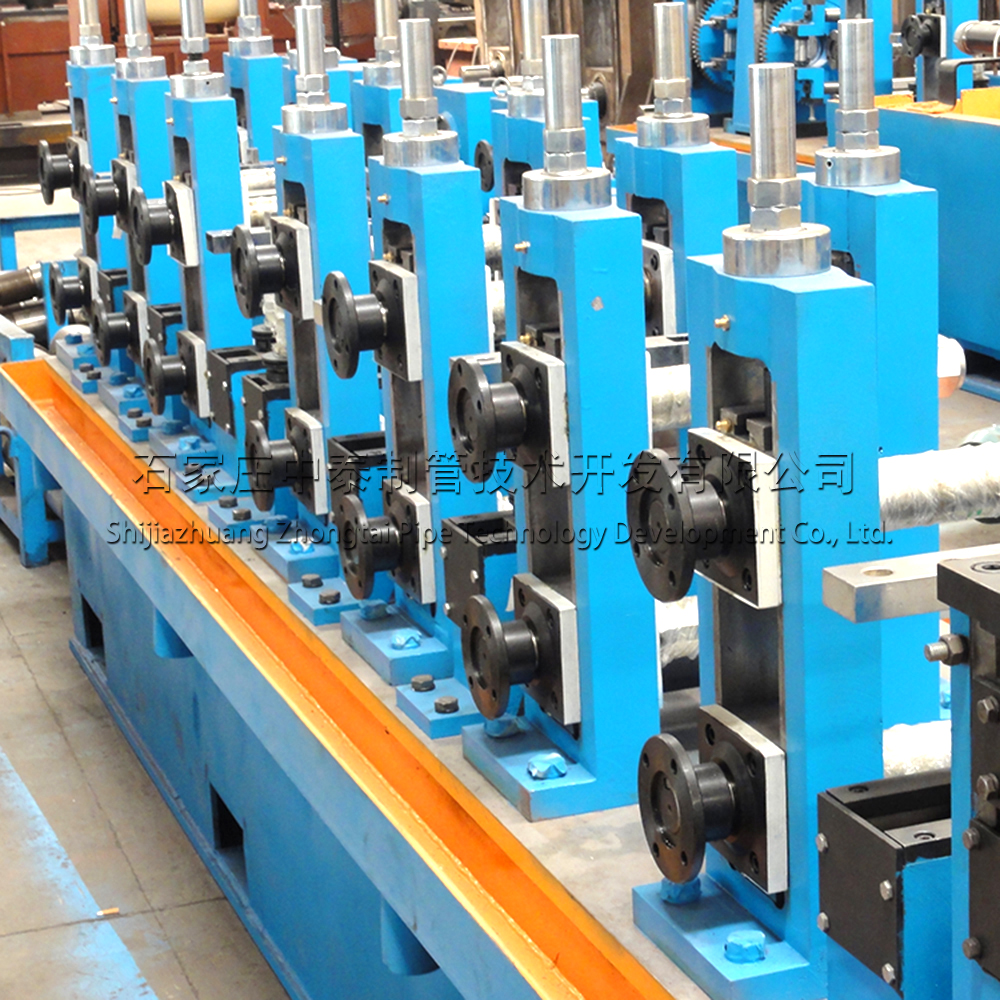

Pabrik tabung ERW uga diarani garis produksi pipa las longitudinal frekuensi dhuwur. Bahan sing cocog yaiku gulungan gulungan sing digulung panas utawa kadhemen kayata baja karbon polos lan baja kekuatan dhuwur, lsp.

Strip baja wis unrolled dening uncoiler, lan banjur lumebu ing panyimpenan accumulator sawise ngliwati mesin welding butt nyukur. Strip baja wis extruded dening rollers lan dipérang dadi rong bagéan: bagean break-mudhun lan bagean pass nggoleki. Sawise welding induksi frekuensi dhuwur lan bagean ukuran, output pipa dawa sing dibutuhake, dipotong kanthi gergaji mabur, lan pungkasane tumpukan lan ngemas pipa baja. Lini produksi iki minangka baris produksi lengkap lengkap kanggo welding terus-terusan saka strip baja menyang pipa,utamané dumadi saka uncoiler, nyukur & welder pungkasan, akumulator, mesin mbentuk & ukuran, Tukang las HF, gergaji mabur, mesin tumpukan & packing.

Yen ana tujuan utawa syarat khusus kanggo pipa baja, perlu nambah peralatan uji coba, kayata mesin uji hidrolik, mesin annealing frekuensi menengah, mesin deteksi cacat ultrasonik, lsp.

Line produksi pipa gandheng frekuensi dhuwur utamane digunakake kanggo produksi terus-terusan pipa gandheng jahitan lurus. Iki nganggo welding induksi frekuensi dhuwur, sing ora mung bisa ngasilake pipa bunder nanging uga pipa persegi sing cocog lan pipa berbentuk khusus. Mesin welding pipa frekuensi dhuwur utamane digunakake kanggo produksi macem-macem pipa wesi, pipa konstruksi, pipa struktural, pipa banyu, pipa minyak, Pipa API, lan liya-liyane.

Taliran eknis

Gulung munggah → Uncoiling → Shear and Welding → Spiral accumulator → Forming → HF induction welding → External burr removing → Cooling → Sizing → Flying saw → Run out table → Inspecting → Packing → Warehouse

Fproses orming

| Pipa bunder | Proses pembentukan gulungan kadhemen | Desain roller apik |

| Skere & pipa persegi panjang | Proses umum babak-kanggo-kotak | Proses mbentuk stabil |

| Bunder-kanggo-alun karo sirah Turki | Kualitas pipa apik |

Informasi Teknis Dasar Jalur Produksi Pipa Las

| Produk & Hasil | Pipa Bundar | 89mm-219Ketebalan mm:2.0mm-8.0mm |

| Tabung Square & Rectangle | 70mm ×70 mm -170mm ×170Ketebalan mm:2.0mm-6.0mm | |

| dawa | 6m-12m Dawane Toleransi: ± 3mm | |

| Kacepetan Produksi | 20-50m/min | |

| Kapasitas Produksi | 35,000 ton/taun | |

| Konsumsi | Mill diinstal Kapasitas | 280 kw |

| Area Line | 100m (dawa) ×9m (jembaré) | |

| Buruh | 6-8 buruh | |

| Bahan Baku | Bahan | Kumparan Baja Karbon Q235B(ASTM GR·D,σs 230) |

| Jembar | 280mm-69Ketebalan 0 mm:2.0mm-8.0mm | |

| ID koil | 600-800 mm | |

| Koil OD | Maks2000 mm | |

| Bobot Coil | 8,0t |

Kaluwihan

1. Efisiensi produksi dhuwur, kacepetan baris bisa nganti 120m / min.

2. Ngasilake dhuwur, mesin bisa dianggo kanthi stabil kanthi kacepetan dhuwur, sing nambah ngasilake produk.

3. Kurang pemborosan, pemborosan unit sing sithik lan biaya produksi sing murah.

4. Akurasi dhuwur, kesalahan diameter mung 0,5 / 100 saka pipa OD.

Produk: GI, baja karbon lan tabung stainless steel kanggo metalurgi, konstruksi, transportasi, mesin lan industri kendaraan.

| ERW TUBE MILL LINE | |||||

| Model | Rpipa udud mm | Alun-alunpipa mm | kekandelan mm | Nyambut gawe m/min | |

| ERW20 | Ф8-Ф20 | 6x6-15×15 | 0.3-1.5 | 120 | Waca liyane |

| ERW32 | Ф10-Ф32 | 10×10-25×25 | 0.5-2.0 | 120 | |

| ERW50 | Ф20-Ф50 | 15×15-40×40 | 0.8-3.0 | 120 | |

| ERW76 | Ф32-Ф76 | 25×25-60×60 | 1.2-4.0 | 120 | |

| ERW89 | Ф42-Ф89 | 35×35-70×70 | 1.5-4.5 | 110 | |

| ERW114 | Ф48-Ф114 | 40×40-90×90 | 1.5-4.5 | 65 | |

| ERW140 | Ф60-Ф140 | 50×50-110×110 | 2.0-5.0 | 60 | |

| ERW165 | Ф76-Ф165 | 60×60-130×130 | 2.0-6.0 | 50 | |

| ERW219 | Ф89-Ф219 | 70×70-170×170 | 2.0-8.0 | 50 | |

| ERW273 | Ф114-Ф273 | 90×90-210×210 | 3.0-10.0 | 45 | |

| ERW325 | Ф140-Ф325 | 110×110-250×250 | 4.0-12.7 | 40 | |

| ERW377 | Ф165-Ф377 | 130×130-280×280 | 4.0-14.0 | 35 | |

| ERW406 | Ф219-Ф406 | 170×170-330×330 | 6.0-16.0 | 30 | |

| ERW508 | Ф273-Ф508 | 210×210-400×400 | 6.0-18.0 | 25 | Waca liyane |

| ERW660 | Ф325-Ф660 | 250×250-500×500 | 6.0-20.0 | 20 | Waca liyane |

| ERW720 | Ф355-Ф720 | 300×300-600×600 | 6.0-22.0 | 20 | Waca liyane |

| LINE PRODUKSI PIPA STAINLESS STEEL | |||||

| Model | Rpipa udud mm | Alun-alunpipa mm | kekandelan mm | kacepetan kerja m/min | |

| SS25 | Ф6-Ф25 | 5×5-20×20 | 0.2-0.8 | 10 | Waca liyane |

| SS32 | Ф6-Ф32 | 5×5-25×25 | 0.2-1.0 | 10 | Waca liyane |

| SS51 | Ф9-Ф51 | 7×7-40×40 | 0.2-1.5 | 10 | Waca liyane |

| SS64 | Ф12-Ф64 | 10×10-50×50 | 0.3-2.0 | 10 | Waca liyane |

| SS76 | Ф25-Ф76 | 20×20-60×60 | 0.3-2.0 | 10 | Waca liyane |

| SS114 | Ф38-Ф114 | 30×30-90×90 | 0.4-2.5 | 10 | Waca liyane |

| SS168 | Ф76-Ф168 | 60×60-130×130 | 1.0-3.5 | 10 | Waca liyane |

| SS219 | Ф114-Ф219 | 90×90-170×170 | 1.0-4.0 | 10 | Waca liyane |

| SS325 | Ф219-Ф325 | 170×170-250×250 | 2.0-8.0 | 3 | Waca liyane |

| SS426 | Ф219-Ф426 | 170×170-330×330 | 3.0-10.0 | 3 | Waca liyane |

| SS508 | Ф273-Ф508 | 210×210-400×400 | 4.0-12.0 | 3 | Waca liyane |

| SS862 | Ф508-Ф862 | 400×400-600×600 | 6.0-16.0 | 2 | Waca liyane |